Engineering

Submarine Pipeline and Riser Systems

Subsea Production Systems and Subsea Products

Floating Production Systems

Oilfield Integrity Management

Design capabilities:

Design of submarine pipelines in conventional shallow to medium-depth waters;

Design of submarine pipelines in deep waters;

Design of deepwater steel catenary risers (SCRs);

Jumper design;

Design of onshore pipelines;

Design of various types of piping, including ordinary carbon steel (CS) pipes, corrosion-resistant alloy (CRA) pipes, unbonded flexible pipes, and bonded flexible pipes;

Front-end engineering and conceptual design, basic design, detailed design, procurement, and technical support for field construction.

Latest achievements:

Design of submarine pipelines and SCRs in 1,500m-deep water;

Design of submarine pipelines resistant to high-frequency cyclic loading based on the elastoplasticity theory;

Design of stationary risers in 300m-deep water;

Design of vertical rigid jumpers in 1,000m-deep water.

Projects:

1. “Deep Sea No. 1” Large Gas Field Development Project

Project location: South China Sea

Time: 2019

Scope of work: detailed design of 12 rigid submarine pipelines, five flexible pipelines, six SCRs and 28 jumpers, procurement, and onsite technical support & services

Client information: CNOOC China Limited

2. Liuhua 29-1 Oilfield Development Project

Project location: South China Sea

Time: 2018

Scope of work: detailed design of two rigid pipelines, two flexible pipelines and five jumpers, procurement, and onsite technical support & services

Client information: Husky Oil China Ltd & CNOOC China Limited

3. Hong Kong LNG Terminal Project

Project location: Hong Kong, China

Time: 2020

Scope of work: detailed design of 30” and 20” submarine pipelines, procurement, and onsite technical support & services

Client information: CLP Power Hong Kong Limited (CLP) and Hongkong Electric Co., Ltd (HKE)

Design capabilities:

Process design and flow assurance design;

Overall design and drilling center arrangement;

Design of hydraulic systems;

Design of power supply and communication systems;

Integrated umbilical design;

Design of subsea structures;

Material selection and corrosion protection design.

Latest achievements:

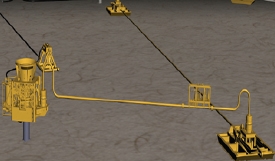

Design of pipeline end termination (PLET) at 1,500m depth;

Design of subsea distribution unit (SDU) at 500m depth;

Design of subsea multi quick connectors (MQCs);

Design of subsea connectors;

Design of subsea hydraulic flying leads (HFL);

Design of subsea pig launcher and receiver (PLR);

Design of multipurpose subsea manifolds with control systems.

Projects:

1. Jinzhou 31-1 Gas Field Development Project

Project location: Bohai Sea, China

Time: 2019

Scope of work:Process design and flow assurance design,Hydraulic system design;Power supply system design,Communication system design,Design of subsea manifolds with complex control systems, jumpers betweensubsea Christmas trees and manifolds, electrical and hydraulic flyingleads, and associated protective structures;Assistance to project owner and technicalsupport for procurement and onshore/offshore construction.

Client information: CNOOC China Limited

2. “Deep Sea No. 1” Large Gas Field Development Project

Project location: South China Sea

Time: 2019

Scope of work:Design of 25 PLETs of 11 types that can be installed by S-Lay, J-Lay or board-side installation method,Design of 11 sets of PLR, one subseathree-way skid, and one underwater pressure drilling module,Design of tubing for subsea central manifolds with control systems,Subsea productionsystem (SPS) document review, fabrication, testing, installation, and pre-commissioning technical support.

Client information: CNOOC China Limited

3. Liuhua 16-2 Oilfield Development Project

Project location: South China Sea

Time: 2018

Scope of work:Design of eight board-side mounted PLETs (with four horizontal connectors and four vertical connectors),Design of four sets of type “I” deepwater PLR,Installation design and offshore operation support.

Client information: CNOOC China Limited

4. Liuhua 29-1/29-2 Deepwater Gas Field Development Project

Project location: South China Sea

Time: 2018

Scope of work:Design of 1,000m key subsea products (PLET + subsea manifold + PLR),Design of composite tieback system for multiple subsea wellheads arranged atvarying space in limited space,Solutions to various difficulties in the installation, operation and maintenance of subsea production systems.

Client information: Husky Oil China Ltd &CNOOC China Limited

5. Wenchang 10-3 Gas Field Development Project

Project location: South China Sea

Time: 2016

Scope of work:Design of complete subsea production systems,Design of subsea manifolds and umbilical terminals without the need for diving operations,Technical supportParticipation forin offshore testing and pre-commissioning, provision of technical support.

Client information: CNOOC China Limited

Design capabilities:

Design of FPSO topsides & hulls and semi-submersible production platforms;

General design of mooring systems;

Basic design of tension-leg platforms (TLPs), SPAR, FLNG, and cylindrical FPSO units,

Optimal design of main dimensions of floating production platforms;

Hydrodynamic analysis;

Model testing, calibration and analysis;

Design and analysis of deepwater mooring systems;

Structural design of floating production platforms;

Hull design for floating production platforms;

Integration and coupling analysis of floating offshore wind platforms.

Latest achievements:

Hydrodynamic analysis;

Model testing, calibration and analysis;

Design and analysis of deepwater mooring systems;

Structural design of floating production platforms;

Hull system design for floating production platforms;

Integration and coupling analysis of floating offshore wind platforms.

Projects:

1. “Deep Sea No. 1” Energy Station Detailed Design Project

Location: South China Sea

Time: 2019

Scope of work:FEED of topside and hullDetailed design of the hull and topside of the 1,500m semi-submersible platform,Involvement in procurement, construction, installation, commissioning, and other supporting services as a main participant.

Client information: CNOOC China Limited

2. Petrobras FPSO P67 & P70 Detailed Design Project

Location: Brazil

Time: 2019

Scope of work:Detailed design of the topsides and hulls of 350,000 T ultra-largeFPSO units operating in 2,200m-deep waters,Application and management of 2D/3D intelligent designs complying with international standards.

Client information (full name): Petrobras

3. HAI YANG SHI YOU 122 Cylindrical FPSO Vessel Detailed Design Project

Location: South China Sea

Time: 2022

Scope of work:FEED of the topside of the cylindrical FPSO vesselDetailed design of the topside, hull and mooring system of the cylindrical FPSO vessel,Procurement,construction, installation and commissioning support.

Client information: CNOOC China Limited

4. Hengyi (Brunei) CLAM Single-point System Design Project

Location: Brunei

Time: 2019

Scope of work:Feasibility study for the CALM single-point system,Basic design and detailed design of the CALM single-point system,EPC support.

Client information (full name): Zhejiang Hengyi Group Co., Ltd

5. FEN JIN FPSO Vessel Single-point Mooring System (SPM) Design Project

Location: South China Sea

Time: 2022

Scope of work:Design of submerged turret production (STP) system,Design for theutilization of old torrent of the STP system.

Client information: CNOOC China Limited

Technological capabilities:

Life extension assessment of platform structure;

Damage evaluation of platforms in service;

Abandonment and dismantling of platforms;

Preparation of risk-based inspection and test plans;

Engineering critical assessment (ECA) of cracks;

Platform vibration-based damage detection;

Platform structure monitoring;

Platform reinforcement and repair;

Digital twin and digital twin-based operation and maintenance.

Latest achievements:

Load prediction software for floating units;

Structural safety evaluation software for hulls, risers, anchor chains, and subsea structures;

Integrity diagnosis software system;

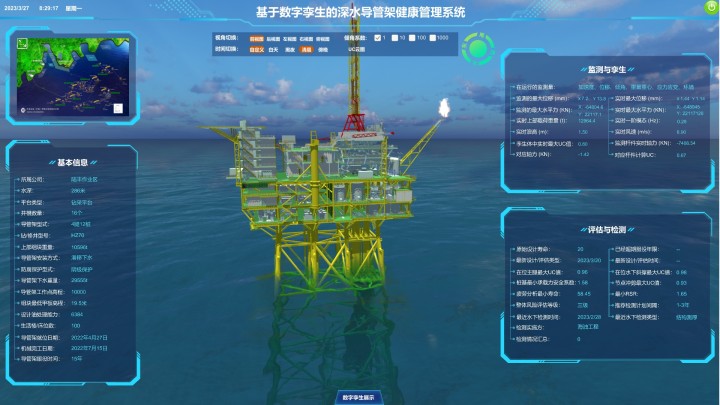

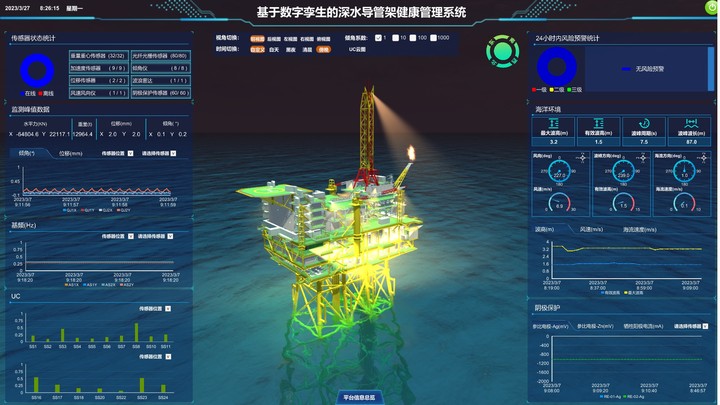

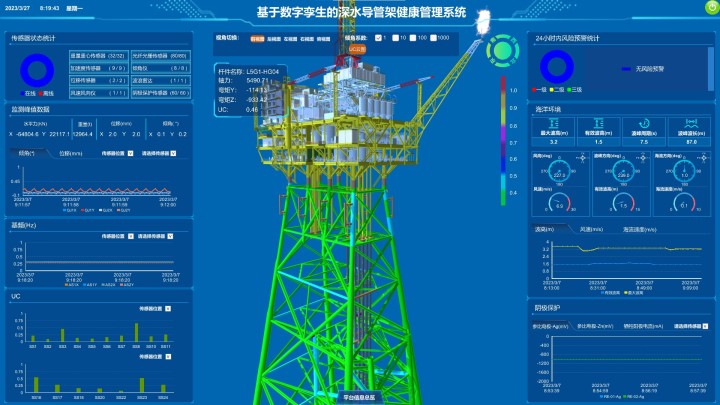

Digital twin-based health management system for deepwater jackets.

Projects:

1. Life Extension Assessment of Qikou 17-3 and Qikou 18-1 Oilfields

Project location: Bohai Sea, China

Time: 2016

Scope of work:Assessment and technical services for prolonging the design service life of platform structure, submarine pipeline, and topside equipment and facilities.

Client information: CNOOC China Limited

2. Jinzhou 21-1WHPA and Jinzhou 20-2SW Platforms and Related Submarine Pipelines and Cables Abandonment and Dismantlement Project

Project location: Bohai Sea, China

Time: 2015

Scope of work:Design and operation construction for the abandonment and dismantlement of various facilities, including the platform structure, submarine pipelines and cables as general contractor.

Client information: CNOOC China Limited

3. Research and Application of Key Safety Assurance Technologies for the Structures and Systems of Jacket Platforms in the Eastern South China Sea

Project location: South China Sea

Time: from 2018 to 2019

Scope of work:Data collection and collation, structure sensitivity analysis, life extension assessment, inspection and test planning, monitoring system construction, digital application of integrity management software, and other related technical services.

Client information: CNOOC China Limited

4. Dongfang 13-2WHPA Platform Emergency Repair Project

Project location: South China Sea

Time: 2020

Scope of work:Emergency safety evaluation, design for emergency repair, offshore repair.

Client information: CNOOC China Limited

5. Digital Twin-based Health Management System for “Deep Sea No. 1” Deepwater Jacket

Project location: South China Sea

Time: 2021

Scope of work:Design, integration, installation and testing of the deepwater jacket monitoring system, development of digital twin algorithms, construction of digital twin software, and technical services for digital twin-based operation and maintenance.

Client information: CNOOC China Limited

The Company has the capacity to design dee-water subsea production systems and products. The Company has delivered more than 30 projects of subsea systems and products, made breakthroughs from zero capacity to developed capacity in many areas, and successfully forged its path to the subsea systems and products design market.

The Company has the capacity to design subsea production systems for service in 1500 m deep waters.

The Company has the capacity to design various subsea equipment for service in 1500 m deep waters, such as PLET, PLEM, ILM, subsea template, subsea manifold and SUTA, and has made periodic progress in the research and development of critical subsea equipment including subsea connector, subsea distribution unit, subsea separator, subsea control module, etc.

The Company has made great technological breakthroughs in various areas, such as jacket structure, subsea pipe structure, single-point mooring system and FPSO monitoring. Relying on the many years of experience in project design and evaluation, COOEC Engineering Company has secured a domestic dominant position in terms of technical strength, especially in the areas of deep-water jacket platform structural integrity and subsea pipeline integrity.